What is the role of a fuse?

What is a fuse?

A fuse refers to an electrical device that, when the current exceeds a specified value, uses the heat generated by itself to fuse the melt and disconnect the circuit. A fuse is a device that uses the heat generated by itself to melt the molten metal after the current exceeds the specified value for a period of time, thereby causing the circuit to disconnect; A current protector made using this principle. Fuses are widely used in high and low voltage distribution systems, control systems, and electrical equipment. As short circuit and overcurrent protectors, they are one of the most commonly used protective devices.

operational principle

An electrical device that uses a metal conductor as a molten material in series in a circuit. When an overload or short circuit current passes through the molten material, it melts due to its own heating, thereby breaking the circuit. Fuses have a simple structure and are convenient to use. They are widely used as protective devices in power systems, various electrical equipment, and household appliances.

The difference between fuses and circuit breakers:

The similarity is that both can achieve short circuit protection. The principle of a fuse is to use the current flowing through the conductor to cause the conductor to heat up. After reaching the melting point of the conductor, the conductor melts, so disconnecting the circuit protects electrical appliances and circuits from being burned out. It is an accumulation of heat, so overload protection can also be achieved. Once the melt burns out, it needs to be replaced.

A circuit breaker can also achieve short-circuit and overload protection for circuits, but the principle is different. It achieves short-circuit protection through the magnetic effect of current (electromagnetic release), and overload protection through the thermal effect of current (not melting, so there is no need to replace components). In practice, when the electrical load in the circuit approaches the load of the fuse used for a long time, the fuse will gradually heat up until it melts. As mentioned above, the melting of a fuse is the result of the combined action of current and time to protect the circuit, and it is one-time. A circuit breaker is a device that automatically opens when the current in the circuit suddenly increases and exceeds the load of the circuit breaker. It provides protection for an instantaneous increase in current in the circuit, such as when there is a large leakage, short circuit, or high instantaneous current. When the cause is identified, the switch can be closed and continue to be used. As mentioned above, the melting of a fuse is the result of the combined action of current and time, while a circuit breaker will trip as soon as the current exceeds its set value, and the effect of time can be almost ignored. Circuit breakers are commonly used components in low-voltage distribution. There are also some places where fuses are suitable.

Structural characteristics

The rated current of the melt is not equal to the rated current of the fuse. The rated current of the melt is selected according to the load current of the protected equipment. The rated current of the fuse should be greater than the rated current of the melt and determined in conjunction with the main electrical appliance.

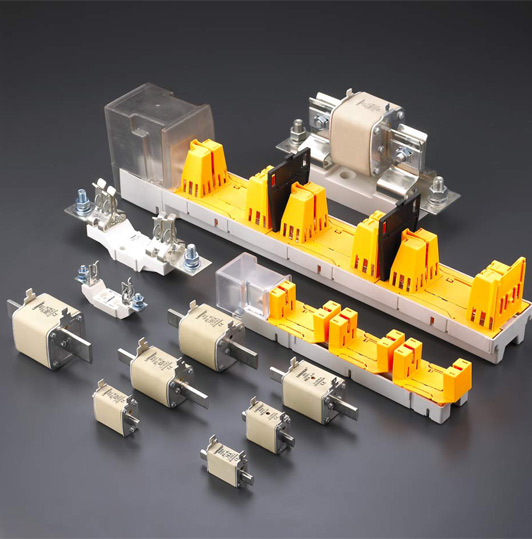

The fuse mainly consists of three parts: the melt, the shell, and the support, among which the melt is the key component that controls the melting characteristics. The material, size, and shape of the melt determine the melting characteristics. Melt materials are divided into two categories: low melting point and high melting point. Low melting point materials such as lead and lead alloys have a low melting point and are prone to melting. Due to their high electrical resistivity, the cross-sectional size of the molten material is larger, and more metal vapor is generated during melting. They are only suitable for fuses with low breaking capacity. High melting point materials such as copper and silver have a high melting point and are not easy to melt. However, due to their low electrical resistivity, they can be made into smaller cross-sectional sizes than low melting point melts. They produce less metal vapor during melting and are suitable for fuses with high breaking capacity. The shape of the melt can be divided into two types: filamentous and strip-shaped. Changing the shape of the variable cross-section can significantly alter the melting characteristics of the fuse. Fuses have various different melting characteristic curves, which can be suitable for the needs of different types of protected objects.